A Step-by-Step Guide to Reloading Cartridges with RCBS's R&D Engineer & Product Line Manager, Steve Koch.

Reloading your own ammunition can be an intimidating process, especially for beginners. However, with the right tools and guidance, it becomes not only manageable but also deeply satisfying. In this tutorial I will go through the entire reloading process for a .223 Remington cartridge using RCBS products. Whether you’re a seasoned reloader or a novice just starting out, this guide will equip you with the knowledge and confidence to reload with precision and safety.

The Importance of a Good Reloading Manual

Every successful reloading session begins with a reliable reloading manual. These manuals are a treasure trove of information, providing detailed instructions on the reloading process and offering critical data on charge weights for various powders. Understanding the correct powder charge is essential to ensure your reloads are safe and perform as expected. Refer to the manual for charge weights, safety guidelines and overall best practices.

Cartridge Gauges: A Crucial Tool

One of the first steps in the reloading process is to assess the condition of your fired cases. RCBS cartridge gauges are invaluable in this regard. These gauges allow you to quickly determine if a fired case needs resizing. For instance, if the case doesn’t fit into the gauge, it indicates that resizing is necessary. Resizing ensures the case will fit back into your firearm’s chamber, maintaining both safety and performance.

Setting Up the Sizing Die

With your cases inspected, it’s time to resize them. We’ll be using the RCBS Rock Chucker Press and the appropriate sizing die. Start by screwing the die into the press. Raise the press ram until it makes contact with the shell holder, then lower the ram and turn the die a quarter turn further to get that crucial cam-over action. This cam-over helps eliminate tolerance slack in the press, ensuring the cartridge case is sized correctly and headspaced properly. Lock the lock ring and you’re ready to begin resizing.

Trimming, Deburring & Lubricating the Cases

Before sizing, it’s important to ensure your cases are trimmed to the proper length. Trimming prevents the case from becoming too long, which can cause feeding and chambering issues. Once trimmed, deburr the case using the RCBS Brass Boss. Deburring smooths out any rough edges on the inside and outside of the case mouth, ensuring smooth bullet seating later on.

Next, lubricate the cases using RCBS Case Slick. A simple method is to place a few cases in a box, give a couple of quick squirts and then shake the box to distribute the lube evenly. Proper lubrication is essential to avoid damaging your cases or the die during the resizing process. After lubing, place the case in the shell holder, run the press and resize the case. To confirm proper resizing, drop the case back into the gauge - it should fit perfectly.

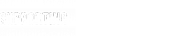

Priming the Case

With the case resized, it’s time to prime it. For this step, we’ll use the RCBS Universal Hand Priming Tool, which is compatible with various primer sizes. Insert a small rifle primer into the tool, set the case in the universal case holder and prime the case. Ensure the primer is seated flush or slightly below the case head (about 0.003 inches). Properly seated primers are crucial for reliable ignition.

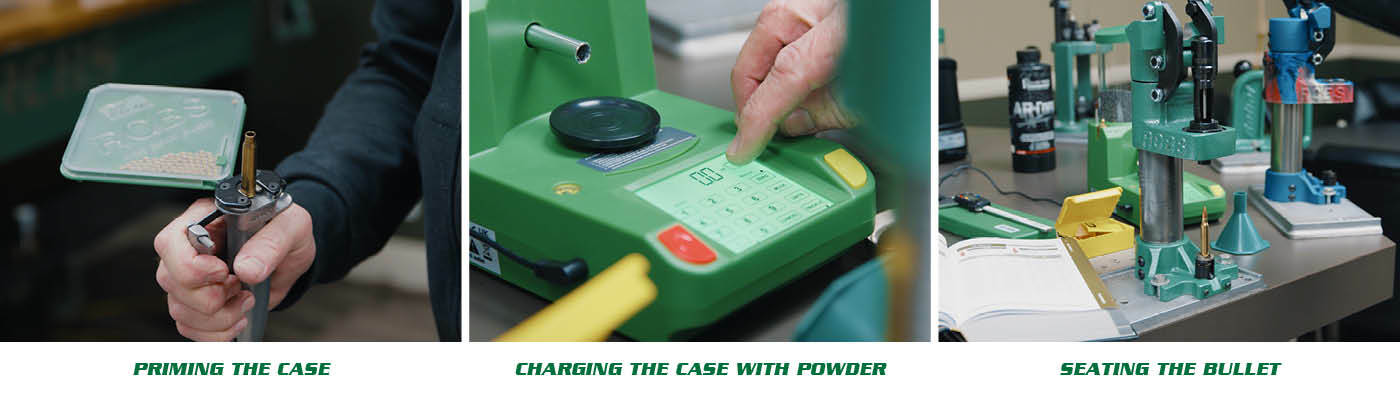

Charging the Case with Powder

Now, we move on to charging the case with powder using the RCBS ChargeMaster Link. Before each session, it’s good practice to calibrate the scale to ensure accurate measurements. Follow the calibration steps: zero the scale, calibrate with the provided weights (50g and 100g) and ensure it reads accurately.

For this demonstration, we’ll use Alliant AR-Comp powder, with a charge weight of 25 grains - a middle-ground choice based on our reloading manual’s recommendation of 24 to 26.3 grains. Always wear your safety glasses and take all necessary precautions when handling powder.

Set the ChargeMaster Link to dispense 25.0 grains of powder and allow it to dispense the charge. Use a powder funnel to pour the powder into the case, ensuring all the powder makes it into the case without spilling.

Seating the Bullet

With the case primed and charged, it’s time to seat the bullet. The RCBS MatchMaster Seat Die, paired with the Summit Press, makes this process precise and straightforward. The MatchMaster Seat Die features a window for easy bullet loading and a bullet retention system that holds the bullet in place before seating.

Place the bullet into the guide, position the case in the shell holder and press the handle to seat the bullet. It’s important to check the overall length (OAL) of the cartridge - our goal is to keep it under 2.260 inches. In this example, our OAL measures 2.252 inches, which is well within the acceptable range. Additionally, you can double-check the OAL by dropping the finished cartridge into the RCBS cartridge gauge to ensure it doesn’t protrude beyond the gauge’s limits.

Reloading your own ammunition is a rewarding experience that gives you control over your shooting. It’s a process that requires attention to detail and a commitment to safety, but with the right tools - like those from RCBS - you can achieve excellent results every time.